mosmith3asu.github.io

Bio-inspired Passive Power Attenuation Mechanism for Jumping Robot

Manufacturing Report

Team 6 Members:

Cole Brauer @ cbrauer@asu.edu

Fuchen Chen @ fchen65@asu.edu

Nathaniel Rossi @ ntrossi@asu.edu

Mason Smith @ mosmith3@asu.edu

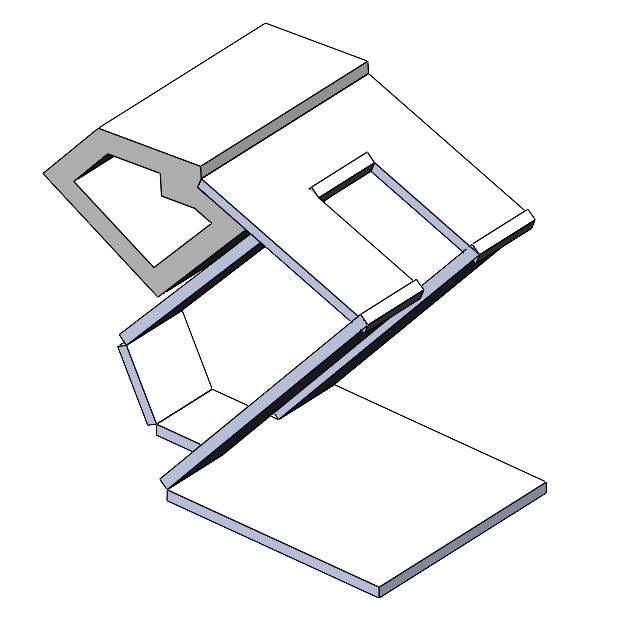

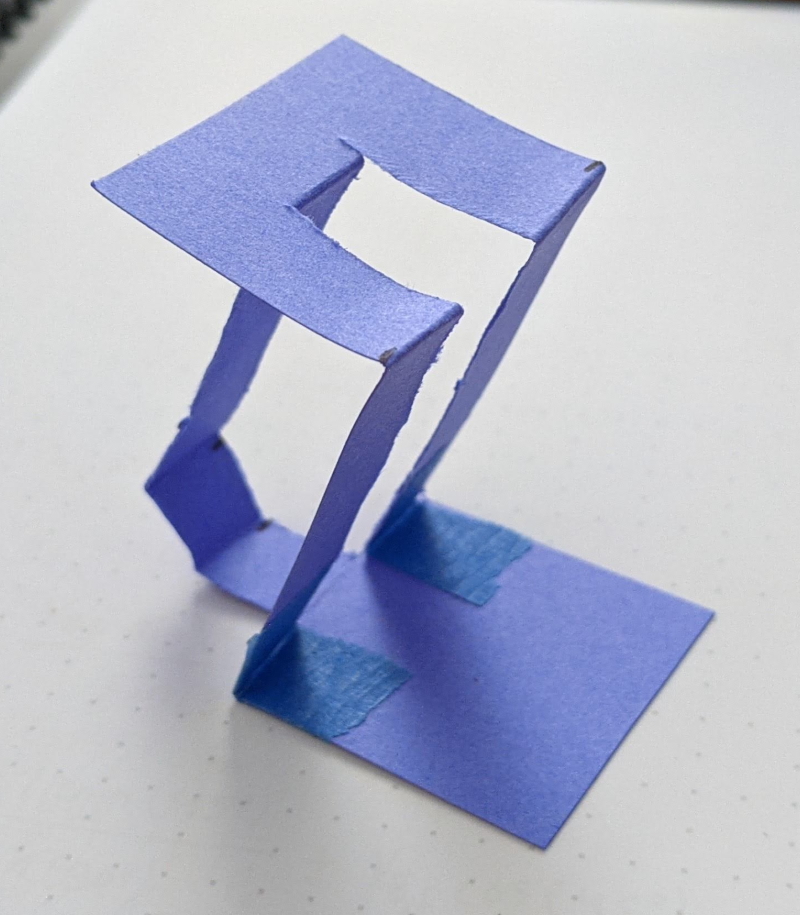

#1. Paper Mockup

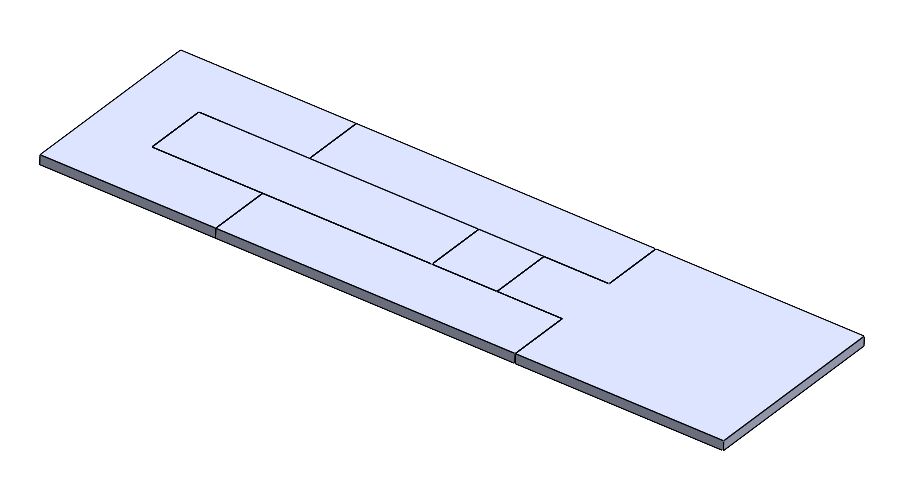

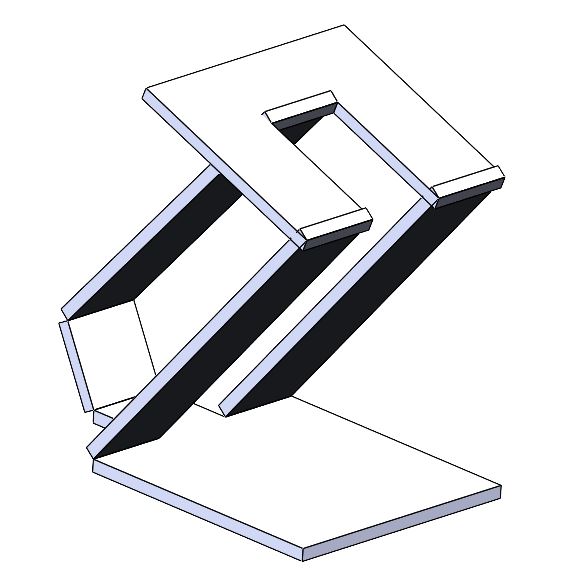

#2. Solidworks Screenshots

A 3D printed part is also designed to represent the upper leg and payload. Adjustment can easily be done to include more weight and mouting structure. To reduce the total weight, double sided tape or super glue will be used to attach the 3D printed part to the laminate robot.

!pip install idealab_tools foldable_robotics shapely

Requirement already satisfied: idealab_tools in /usr/local/lib/python3.7/dist-packages (0.0.22)

Requirement already satisfied: foldable_robotics in /usr/local/lib/python3.7/dist-packages (0.0.29)

Requirement already satisfied: shapely in /usr/local/lib/python3.7/dist-packages (1.7.1)

Requirement already satisfied: imageio in /usr/local/lib/python3.7/dist-packages (from idealab_tools) (2.4.1)

Requirement already satisfied: ezdxf in /usr/local/lib/python3.7/dist-packages (from foldable_robotics) (0.16.1)

Requirement already satisfied: numpy in /usr/local/lib/python3.7/dist-packages (from foldable_robotics) (1.19.5)

Requirement already satisfied: matplotlib in /usr/local/lib/python3.7/dist-packages (from foldable_robotics) (3.2.2)

Requirement already satisfied: pypoly2tri in /usr/local/lib/python3.7/dist-packages (from foldable_robotics) (0.0.3)

Requirement already satisfied: pyyaml in /usr/local/lib/python3.7/dist-packages (from foldable_robotics) (3.13)

Requirement already satisfied: pillow in /usr/local/lib/python3.7/dist-packages (from imageio->idealab_tools) (7.1.2)

Requirement already satisfied: pyparsing>=2.0.1 in /usr/local/lib/python3.7/dist-packages (from ezdxf->foldable_robotics) (2.4.7)

Requirement already satisfied: python-dateutil>=2.1 in /usr/local/lib/python3.7/dist-packages (from matplotlib->foldable_robotics) (2.8.1)

Requirement already satisfied: cycler>=0.10 in /usr/local/lib/python3.7/dist-packages (from matplotlib->foldable_robotics) (0.10.0)

Requirement already satisfied: kiwisolver>=1.0.1 in /usr/local/lib/python3.7/dist-packages (from matplotlib->foldable_robotics) (1.3.1)

Requirement already satisfied: six>=1.5 in /usr/local/lib/python3.7/dist-packages (from python-dateutil>=2.1->matplotlib->foldable_robotics) (1.15.0)

%matplotlib inline

import os

import numpy

import shapely.geometry as sg

from math import pi, sin,cos,tan

import idealab_tools.text_to_polygons

import foldable_robotics

from foldable_robotics.layer import Layer

from foldable_robotics.laminate import Laminate

import foldable_robotics.manufacturing

import foldable_robotics.parts.castellated_hinge1

import foldable_robotics.dxf

import foldable_robotics.manufacturing

import foldable_robotics.solidworks_support

foldable_robotics.display_height=200

foldable_robotics.line_width=.1

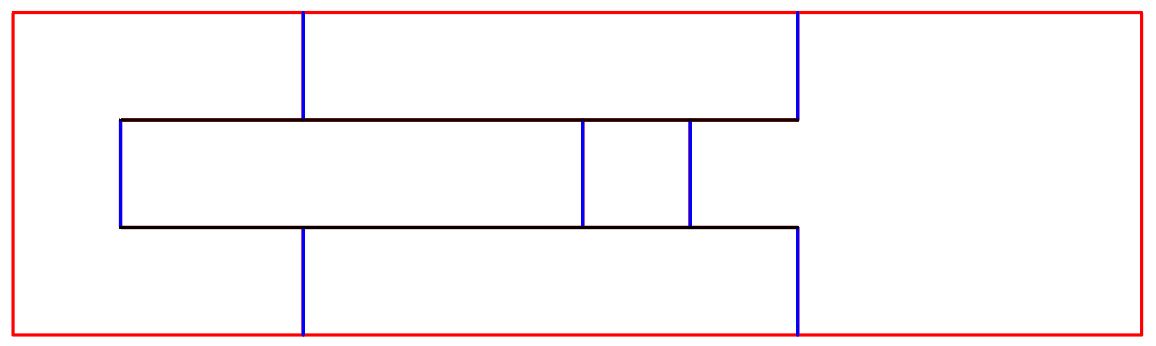

3. Dxf of Body and Joint Layers

Our desgin cannot be exported correctly using the SolidWorks macro, so the part in its flattened state was exported as a dxf file. Then the file is imported to Adobe Illustrator to mark the joints, cuts, and bodies as shown below.

# The file is in the google drive assignment folder

output_file_name = 'design.dxf'

round_digits = 2

prescale=10

jig_diameter = 5

support_width = 1

kerf = .05

jig_hole_spacing=20

is_adhesive = [False,True,False,True,False]

arc_approx = 10

#4. Jupyter notebook Script

# Helper functions

def get_bodies(filename, layername, num_layers):

body = foldable_robotics.dxf.read_lwpolylines(filename,layer=layername, arc_approx = 10)

bodies = [Layer(sg.Polygon(item)) for item in body]

body = bodies.pop(0)

for item in bodies:

body ^= item

body = body.to_laminate(num_layers)

return body

def get_hinge_lines(filename,layername):

hinge_lines1 = foldable_robotics.dxf.read_lines(filename,layer=layername)

hinge_lines2 = foldable_robotics.dxf.read_lwpolylines(filename,layer=layername)

hinge_lines3 = []

for points in hinge_lines2:

hinge_lines3.append(points[:2])

hinge_lines = hinge_lines1 +hinge_lines3

return hinge_lines

def hinge_lines_to_hinges(hinge_lines,hinge):

lam = Layer().to_laminate(len(hinge))

all_hinges = []

for p3,p4 in hinge_lines:

all_hinges.append(hinge.map_line_stretch((0,0),(1,0),p3,p4))

all_hinges = lam.unary_union(*all_hinges)

return all_hinges

def get_cuts(filename,layername,thickness,num_layers):

cut_lines = foldable_robotics.dxf.read_lines(filename,layer=layername)

cut_lines += foldable_robotics.dxf.read_lwpolylines(filename,layer=layername, arc_approx = 10)

cuts = []

for item in cut_lines:

cuts.append(Layer(sg.LineString(item)))

cuts = Layer().unary_union(*cuts)

cuts<<=thickness/2

cuts = cuts.to_laminate(num_layers)

return cuts

def polys_to_layer(l1):

l1 = [sg.Polygon(item) for item in l1]

l11 = Layer(l1.pop(0))

for item in l1:

l11 ^= Layer(item)

return l11

def build_layer_numbers(num_layers, text_size = None, prop=None):

text_size = text_size or 1

prop = prop or {'family':'Arial','size':text_size}

layer_ids = []

for ii in range(num_layers):

l = idealab_tools.text_to_polygons.text_to_polygons('L'+str(ii),prop=prop)

layer_ids.append(l)

layer_ids = [polys_to_layer(item) for item in layer_ids]

layer_id = Laminate(*layer_ids)

return layer_id

def calculate_removable_scrap(design,sheet,width,is_adhesive):

'''this computes all removable scrap given a sheet, a design, and a clearance width'''

all_scrap = sheet-design

ru = foldable_robotics.manufacturing.not_removable_up(design,is_adhesive)

rd = foldable_robotics.manufacturing.not_removable_down(design,is_adhesive)

removable_scrap_up = all_scrap-(ru<<width)

removable_scrap_down = all_scrap-(rd<<width)

removable_scrap = removable_scrap_up|removable_scrap_down

return removable_scrap

def build_web(design2,keepout,support_width,jig_diameter,jig_hole_spacing,is_adhesive):

num_layers = len(design2)

layer_id = build_layer_numbers(num_layers,text_size=jig_diameter)

design_outer = foldable_robotics.manufacturing.unary_union(design2)

bb1= (design_outer<<jig_hole_spacing/2).bounding_box()

(x1,y1),p2 = bb1.bounding_box_coords()

w,h = bb1.get_dimensions()

w2 = round(w/jig_hole_spacing)*jig_hole_spacing

h2 = round(h/jig_hole_spacing)*jig_hole_spacing

points = []

points.append(sg.Point(x1,y1))

points.append(sg.Point(x1+w2,y1))

points.append(sg.Point(x1,y1+h2))

points.append(sg.Point(x1+w2,y1+h2))

layer_id = layer_id.translate(x1+jig_diameter,y1-jig_diameter/2)

placement_holes2 = Layer(*points)

placement_holes2<<=(jig_diameter/2)

sheet = (placement_holes2<<10).bounding_box()

placement_holes2=placement_holes2.to_laminate(num_layers)

sheet=sheet.to_laminate(num_layers)

removable_scrap = calculate_removable_scrap(design2,sheet,support_width,is_adhesive)

web = (removable_scrap-placement_holes2)-layer_id

return web,sheet

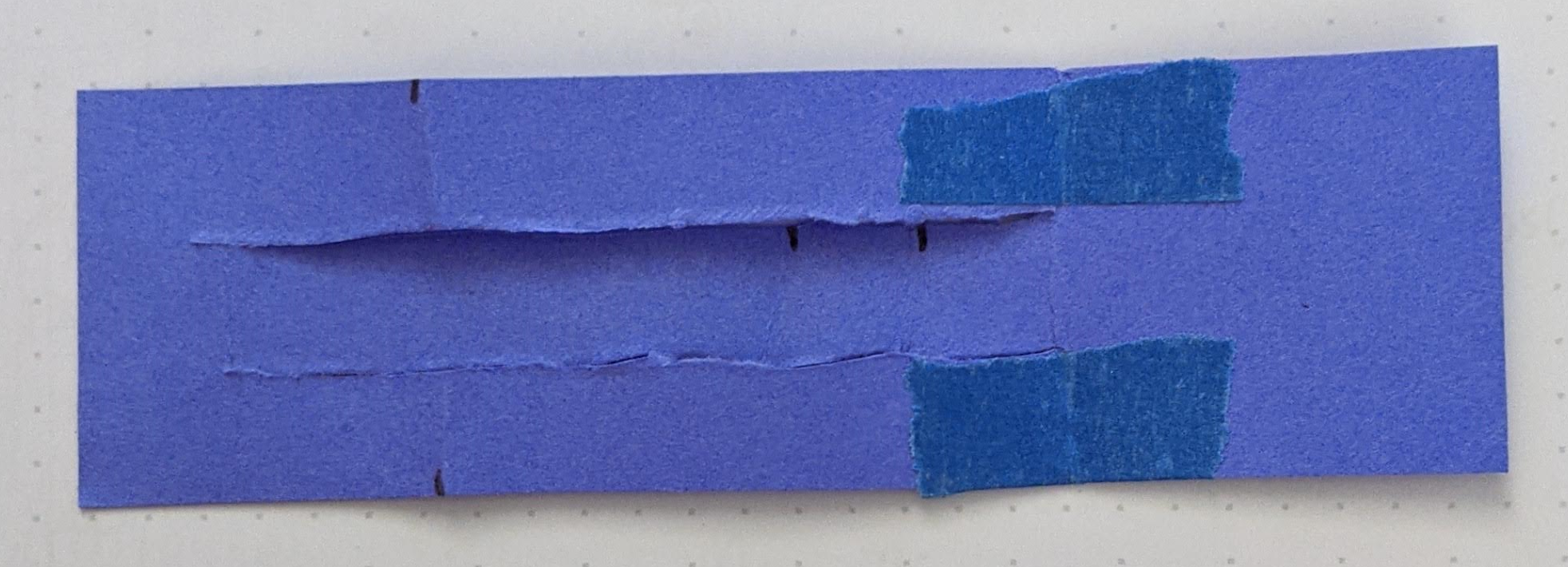

Single Layer Robot Design

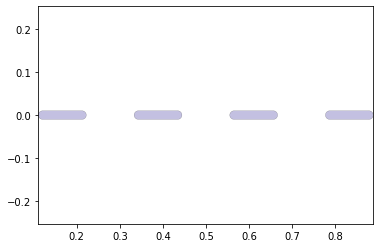

For single layer design, the joint consisits of dashed perforations to weaken the material strength for bending. The density of the perforations can be adjusted for weaker or stronger bending force.

# Single layer hinge

radius = .01

num_perforations = 4 # Even number to end with a perforation

num_segments = num_perforations*2+1

num_points = num_segments+1

a=numpy.r_[0:1:num_points*1j]

lines = []

for ii in range(int(len(a)/2)-1):

p1 = sg.Point(a[2*ii+1]+radius,0)

p2 = sg.Point(a[2*ii+2]-radius,0)

lines.append(sg.LineString((p1,p2)))

hinge = Layer(*lines)

hinge<<=radius

hinge = Laminate(hinge)

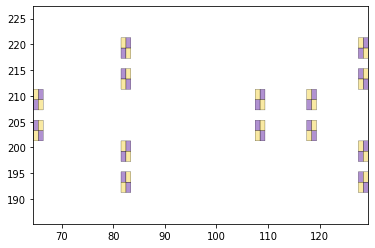

hinge.plot()

# Single layer design

NUMLAYERS = len(hinge)

body = get_bodies(output_file_name,'body',NUMLAYERS)

body = foldable_robotics.manufacturing.cleanup(body,.01)

# body.plot()

joint_lines= get_hinge_lines(output_file_name,'joints')

joints = hinge_lines_to_hinges(joint_lines,hinge)

joints = foldable_robotics.manufacturing.cleanup(joints,.001)

# joints.plot()

cuts = get_cuts(output_file_name,'cuts',.02,NUMLAYERS)

# cuts.plot()

design2 = body - joints - cuts

design2.plot()

!manufacturing/output_16_0.png)

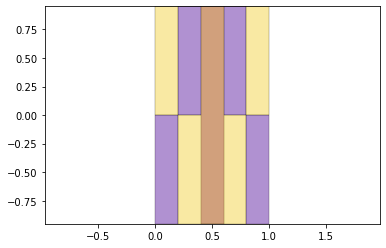

Five Layer Robot Design

For five layer design, the joint is a castellated laminate with fleible damping or spring materials in the middle.

# Five layer hinge

def hinge_width_calculator(desired_degrees,thickness):

theta = (180-desired_degrees)*pi/180

w=thickness/tan(theta)

return w

hinge = foldable_robotics.parts.castellated_hinge1.generate()

w=hinge_width_calculator(150,1.1)

hinge = hinge.scale(1,w)

hinge.plot()

# Five layer design

NUMLAYERS = len(hinge)

body = get_bodies(output_file_name,'body',NUMLAYERS)

body = foldable_robotics.manufacturing.cleanup(body,.01)

# body.plot()

joint_lines= get_hinge_lines(output_file_name,'joints')

joints = hinge_lines_to_hinges(joint_lines,hinge)

joints = foldable_robotics.manufacturing.cleanup(joints,.001)

# joints.plot()

cuts = get_cuts(output_file_name,'cuts',.02,NUMLAYERS)

# cuts.plot()

design2 = body - joints - cuts

design2.plot()

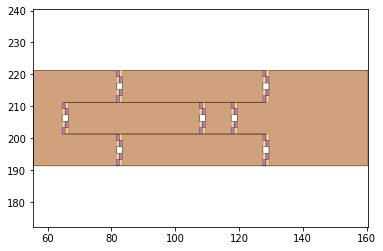

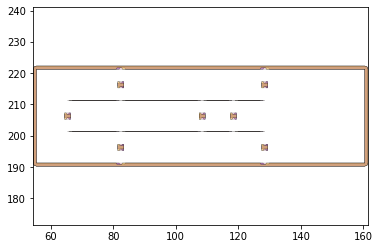

Five Layer Manufacturing Design

# Web design

keepout = foldable_robotics.manufacturing.keepout_laser(design2)

# keepout.plot()

web,sheet=build_web(design2,keepout,support_width,jig_diameter,jig_hole_spacing,is_adhesive)

web.plot()

# sheet.plot()

# Scrap

second_pass_scrap = sheet-keepout

first_pass_scrap = sheet - design2-second_pass_scrap

first_pass_scrap = foldable_robotics.manufacturing.cleanup(first_pass_scrap,.01)

first_pass_scrap.plot()

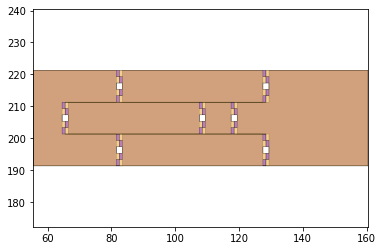

# Support Design

support = foldable_robotics.manufacturing.support(design2,foldable_robotics.manufacturing.keepout_laser,support_width,support_width/2)

support.plot()

# All remaining parts after cut

supported_design = web|design2|support

# supported_design.plot()

cut_material = (keepout<<kerf)-keepout

# cut_material.plot()

final_cut = sheet - keepout

final_cut = final_cut[0]

# final_cut.plot()

remaining_material = supported_design-cut_material

# remaining_material.plot()

d3=design2>>1 # a bit bigger design for matching

remaining_parts = foldable_robotics.manufacturing.find_connected(remaining_material,is_adhesive)

for item in remaining_parts:

if not (item&d3).is_null():

design2_actual = item

design2_actual.plot(new=True) # Plot the most similar remaining parts

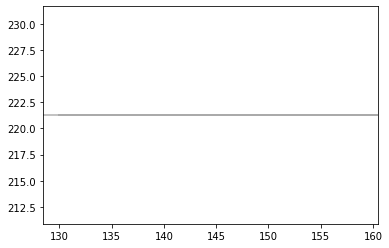

# Similarity check

check = (design2_actual^design2)

check.plot(new=True)

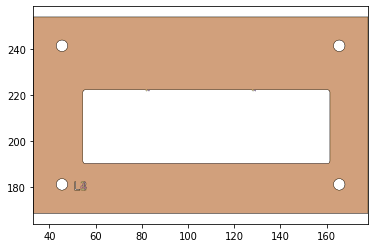

5. Final .dxf files

There are three first pass cut files for the rigid, flexible, and adhesive layers respectively. There is also a final cut file for releasing the design from the laminate.

# Final cut files

w,h = supported_design.get_dimensions()

p0,p1 = supported_design.bounding_box_coords()

rigid_layer = supported_design[0] | (supported_design[-1].translate(w+10,0))

rigid_layer.plot()

l4 = supported_design[3].scale(-1,1)

p2,p3 = l4.bounding_box_coords()

l4 = l4.translate(p0[0]-p2[0]+10+w,p0[1]-p2[1])

adhesive_layer = supported_design[1] | l4

adhesive_layer.plot(new=True)

first_pass = Laminate(rigid_layer,adhesive_layer,supported_design[2])

first_pass.export_dxf('first_pass')

final_cut.export_dxf('final_cut')